Quality inspection report: the so-called quality inspection report refers to the safety and performance test of products, which can be successfully settled in tmall, Jingdong Mall, supermarket and other platforms, or provide consumers with reference standards. According to the three-level standards (national standards, ministerial standards and the enterprise's own standards), the quality assessment shall be carried out, the basic assessment shall be made, and the reasons for the qualified or unqualified quality shall be analyzed.

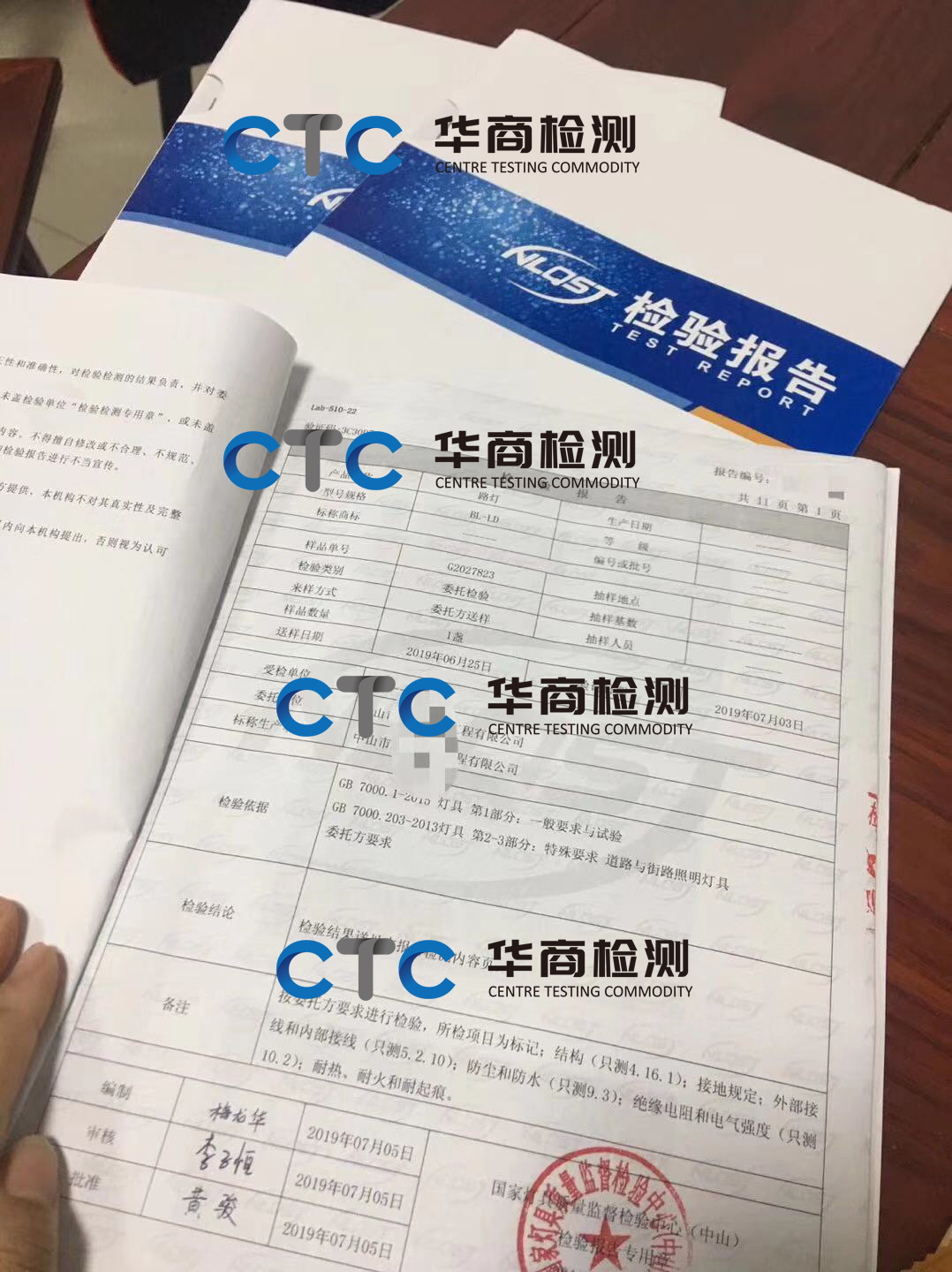

As the quality of products is more and more valued by people, when choosing to sell products, the major shopping malls in the country not only need enterprises to provide certification certificates of relevant products, but also require enterprises to provide a relevant "product quality inspection report" issued by the "authority". The product quality inspection report can comprehensively and objectively reflect the quality information of products, which is generally provided by independent suppliers It is required to be completed by the third party professional inspection agency of Chinese merchants of both parties (it must have two qualification certificates of CNAs and CMA). The third-party professional inspection institution is relatively independent and impartial, and is qualified to issue impartial data (inspection report) to the society.

Product testing is designed to ensure that consumers know which products are right for them and which are valuable. Product testing is a kind of strategy to increase consumer protection by checking the requirements of marketing strategies such as advertising. The essence of these strategies is for the physical distribution services, not for the interests of consumers. The emergence of product testing is the beginning of the modern consumer movement.

Product testing may be performed by manufacturers, independent laboratories, agencies, etc. Existing formal test methods are often used as the basis for testing. At other times, engineers develop test methods that are appropriate for a specific purpose. The comparison test object has several duplicate samples of similar products under the same test conditions.

What is quality inspection report

A lot of people don't understand what a test report is. Why do you need to test? According to the current all products need to pass the quality inspection before you sell them, and the statistics of the qualified number of the company's products are needed, mainly the written certification of the qualified product quality. He got the result through the quality inspection of products and equipment. Is to ensure that the product quality system standards to find Chinese testing center.

2、 Why to make quality inspection report

At present, various shopping malls, online shopping malls and exclusive stores have put forward higher requirements for product testing and certification. Entering tmall and Jingdong have to pass the national standard quality inspection for a series of products. In 2015, tmall made the investment invitation qualification change, which mainly involves "household appliances, 3C digital, cosmetics, food health products, footwear bags, service categories, electronic ticket certificate" Certificate, outdoor sports, clothing "nine categories of investment invitation qualification of the new and revised.

Purpose of handling test report:

Product testing may have several purposes, such as:

1. Determine whether the requirements of specifications, regulations or contracts are met, or verify these requirements,

2. Decide whether a new product development plan is in progress: demonstrate proof of concept

3. Provide standard data for other scientific, engineering and quality assurance functions

4. Verify suitability for * end use

5. Provide basis for technical exchange

6. Provide technical means for comparison of several methods.

7. Provide evidence in legal proceedings: product liability, patent, product claim, etc.

8. Help solve current product problems

9. Help identify potential cost savings for the product

Product testing can be used to:

1. Make the product subject to the expected pressure and power in use

2. Reproduce the type of damage caused to the product due to the use of consumers

Product testing is any process by which researchers measure product performance, safety, quality, and compliance with established standards. The main factor that makes up an objective comparative test procedure is the extent to which researchers can test independently of the manufacturer, supplier and marketing personnel of the product.

The process of product test test report is very simple, which can be summarized as follows:

1. Consult with Chinese manufacturers for testing, and make quotation according to the product testing standard

2. Reach an agreement and sign a contract

3. Send samples for testing

4. After the test, show the test report

5, finish

The testing cycle of the whole product is generally one week, and some items may take a long time, which is determined according to the specific testing items.